Purpose

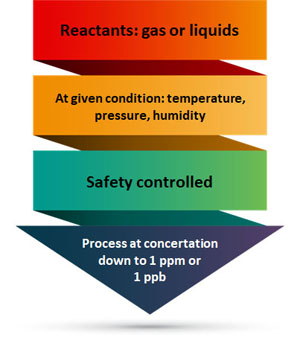

Reactants mixer is suitable for all application where special mixture of gases or liquids is needed e.q. artificial air with defined concentration of pollutants. Required fields are fuel cell testing, sensor testing or other chemical processes.

Capabilities

Costume designed lines are provided to meet demand specific requirements in order to minimalize cost and increase efficiency of system. System enables to control concentration down to 100 – 1 ppm depends on application dynamically or semi dynamically down to 1 ppb.

Fully automated and unattended operation

All functions of reactants mixer are controlled by computer and it is ready for remote control: especially all valves, heaters, mass flow control, pressure control, humidity control. System is fully automated enables unattended operation.

Safety

System contains safety procedures as nitrogen purge and emergency shut down. Working range as temperature sensors are compared with safety limits that can be set. There are two levels of limits.

| Reactants mixer | |

|---|---|

| Controlled concentration | Down to 100-1 ppm depends on application |

| Reactants | Gas or vapors. Non-corrosive or corrosive |

| System | Dynamic control |

| Flow rates | Customized. Typically up to hundreds sccm |

| Gas humidification | Dew point up to 90°C, if it is required |

| Operating temperature | Max 120°C. Higher is optional |

| Operating pressure | 6 Bar |

| Safety | Nitrogen purge, temperature and pressure limits, gas detector (optional), safety interlocks, blackout protection. |

| Extra precise solution | |

| Controlled concentration | Down to 1 ppb. |

| System | Semi dynamic control |